How to choose ceramic corrugated structured packing?

August 13, 2025

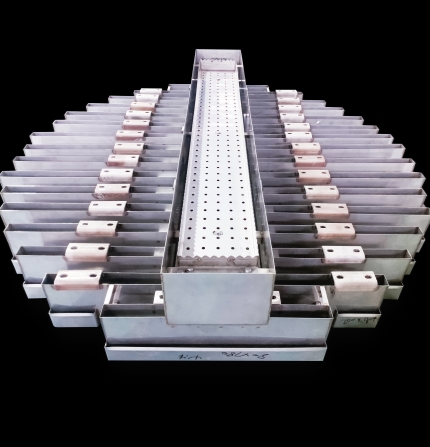

The specifications of ceramic corrugated structured packing are divided into 700Y, 450Y, 350Y, 250Y, 150Y, etc. Different specifications correspond to different product dimensions in terms of length, width, and height.

When consulting ceramic corrugated structured packing, customers generally want to know the specific surface area, bulk density, porosity, inclination angle, pressure drop, theoretical plate number, hydraulic diameter, liquid load, factors and other parameters of different types of products. The length, width, and height parameters, even for the same type of ceramic corrugated filler, have different sizes. The tower diameter varies under different operating conditions, and the required length, width, and height are also different.

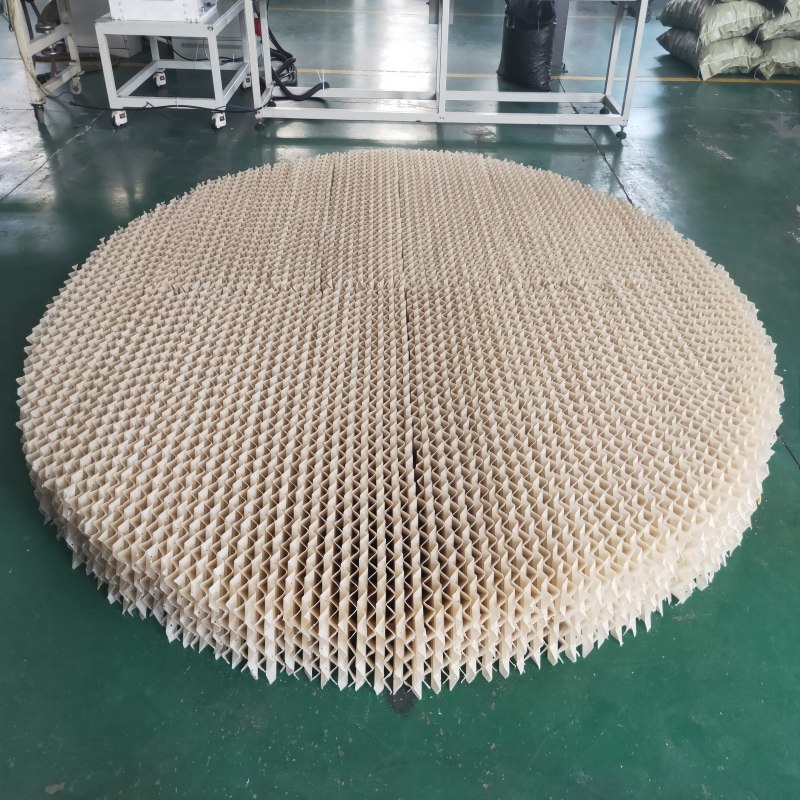

The function of ceramic corrugated structured packing

Due to the unique structure of ceramics, they have good hydrophilicity. The extremely thin liquid film and inclined and tortuous airflow channels can promote the flow of airflow without blocking it, making ceramic fillers compatible with metal fillers. However, their corrosion resistance and high temperature resistance cannot be compared with metal fillers. The surface structure has good wettability, which can accelerate the flow of liquids and minimize the amount of retained liquid in the filler. Thereby reducing the chances of overheating, polymerization, and coking.

The different inclinations can be divided into X-shaped and Y-shaped. X-shaped inclination angle of 300, Y-shaped inclination angle of 450. The X-type pressure drop is relatively small, while the Y-type mass transfer performance is good. To balance pressure drop and mass transfer performance, holes can be opened on the plate. Due to the lack of significant amplification effect of regular packing, its surface roughness is superior to the unique corrosion resistance of the material, and it is used in mass transfer processes such as distillation, stripping, absorption, and extraction in petrochemical industry. Have you learned about the length, width, and height specifications of ceramic corrugated regular packing through the above introduction

Read More

Address : Intersection of Jinguang Avenue and Chongqing Middle Road, Anyuan Industrial Park, Anyuan District, Pingxiang City, Jiangxi

Address : Intersection of Jinguang Avenue and Chongqing Middle Road, Anyuan Industrial Park, Anyuan District, Pingxiang City, Jiangxi Tel :

Tel :  Email :

Email :  WhatsApp :

WhatsApp :  IPv6 network supported

IPv6 network supported