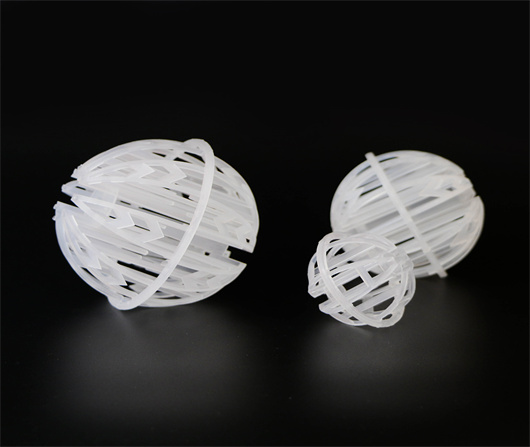

Tri pack is a functional product or device that combines environmental protection concepts and technological innovation, aimed at reducing environmental pollution, improving resource utilization efficiency, or promoting ecological protection. The original intention of its design is to solve environmental problems in daily life or industrial scenarios through simple and reusable methods.

Environmentally friendly ball fillers play various key roles in environmental engineering, which can be further divided into the following aspects:

1、 Physical effects

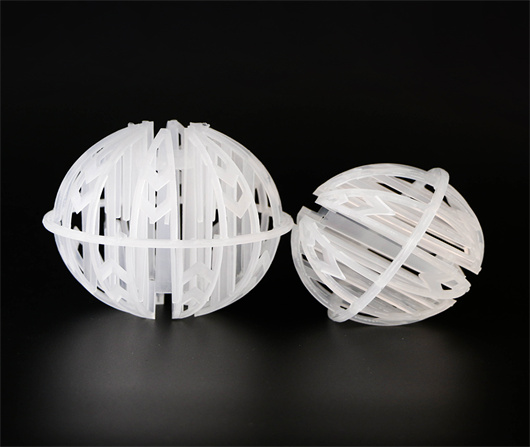

Increase contact area

Porous structure design (such as honeycomb or corrugated) significantly increases the gas-liquid or liquid-liquid contact area, promoting mass transfer efficiency. For example, in an absorption tower, the contact area between exhaust gas and treatment solution can be increased by 3-5 times.

2、 Biochemical action

Biofilm carrier

The specific surface area can reach 800m ²/m ³, providing attachment space for microorganisms such as nitrifying bacteria. A case study of a sewage treatment plant shows that the use of environmentally friendly balls increases the thickness of the biofilm by 2 times and increases the removal rate of ammonia nitrogen by 35%.

Environmentally friendly balls made of different materials (such as PP, PVC, ceramics) are suitable for specific scenarios, and the selection should take into account factors such as pollutant properties, operating temperature, and cost. With the development of surface modification technology, new environmentally friendly balls are evolving towards functionalization (such as magnetism and photocatalysis) and intelligence (such as load sensors