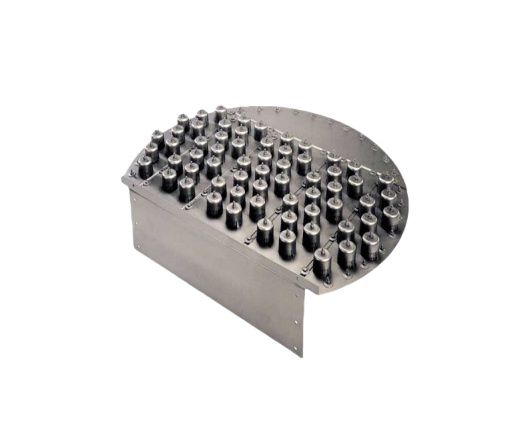

Bubble cap trays are used primarily in applications with very low liquid loading and very high flexibility, where large turndown ratios are required. A bubble cap has riser or chimney fitted over each hole, and a cap that covers the riser. The cap is mounted so that there is a space between riser and cap to allow the passage of vapor. Vapor rises through the chimney and is directed downward by the cap, finally discharging through slots in the cap, and finally bubbling through the liquid on the tray.

Material :

304L 316L 304 2205 2507Advantage of Metal Bubble Cap tray

1.Optimized High Turndown

2.Lowest Leakage when Compared to Sieve or Valve Trays

3.Used for Low Liquid and Vapor Rates

4.High Efficiency

5.Excellent Fouling Protection

Product Detailed Pictures

|

|

Package Description

| Package | Carton Box, Woven Bag,Ton Bag, Wooden case | |||||

| Container | 20GP | 40GP | 40HQ | Normal order | Mininum order | Sample order |

| Quantity | 22CBM | 44CBM | 55CBM | less than 22CBM | 1CBM | less than 5pcs |

| Delivery time | 7days | 14days | 20days | 7days | 3days | stock |

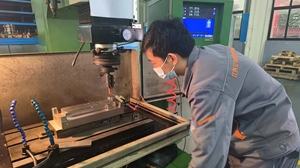

Factory Advantage

| Professional Mass Transfer Manufacturer | ||

|

|

|

| Digital Manufacturing Workshop | Product Design and Customize | Technical Support |

Customer Service

| OEM | ODM | EPC |

|

Annual production :30,000 cubic meters Production Capacity:28 advanced streamlined production lines |

Well-established R&D capabilities Designer with 15 years' experience |

One set of work from project design, purchase,construction to operation ,to provide customer a comprehensive solution. |

|

|

|

|

Application:

Mainly used in reactive distillation, separation of certain organic products; separation of benzene-methyl; separation of nitrochlorobenzene; oxidation and absorption of ethylene.