Size :

25mm,38mm,50mm,76mmMaterial :

304,304L,316,316L,2205,2507,copper,titanium,hastelloyAdvantage of High Performance Metal Random Packing Metal Flat Ring

1.High capacity, low pressure drop , Low aspect ratio increases capacity and reduces pressure drop.

2.The preferred vertical orientation of the packing shaft allows free gas to flow through the packing bed.

3. The low pressure drop and high capacity allow smaller tower diameters and blower sizes to be used in new installations

Product Detailed Pictures

|

|

Technical Data

| Size mm | Surface area m2/m3 | Void fraction % | Bulk number pieces/m3 |

| 25 | 220 | 96.5 | 97160 |

| 38 | 154.3 | 95.9 | 31800 |

| 50 | 109.2 | 96.1 | 12300 |

| 76 | 73.5 | 97.6 | 3540 |

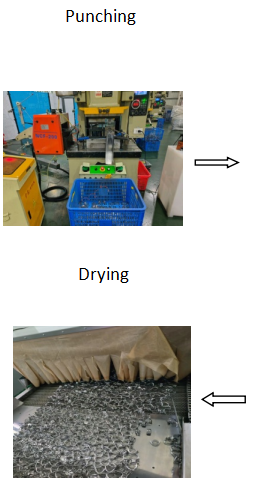

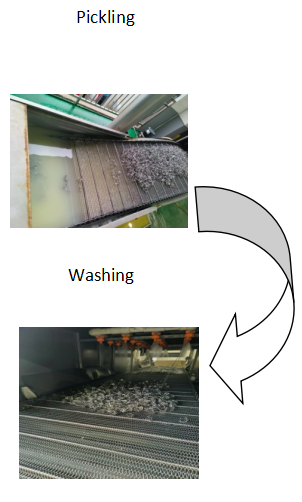

Prodution Process

Package Description

| Package | Carton Box, Woven Bag,Ton Bag, Wooden case | |||||

| Container | 20GP | 40GP | 40HQ | Normal order | Mininum order | Sample order |

| Quantity | 22CBM | 44CBM | 55CBM | less than 22CBM | 1CBM | less than 5pcs |

| Delivery time | 7days | 14days | 20days | 7days | 3days | stock |

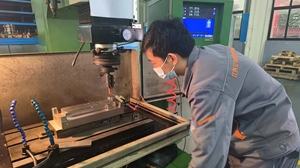

Factory Advantage

| Professional Mass Transfer Manufacturer | ||

|

|

|

| Digital Manufacturing Workshop | Product Design and Customize | Technical Support |

Customer Service

| OEM | ODM | EPC |

|

Annual production :30,000 cubic meters Production Capacity:28 advanced streamlined production lines |

Well-established R&D capabilities Designer with 15 years' experience |

One set of work from project design, purchase,construction to operation ,to provide customer a comprehensive solution. |

|

|

|

|

Application:

1.Used in absorption and stripping services , Ethylene primary fractionator and quench tower , heat transfer .

2.Used in flue gas desulfurization ,various separation processes, including separation of methanol and organic acids.