Size :

16mm,25mm,30mm,38mm,50mmMaterial :

CeramicAdvantages of Random Packing Ceramic Flat Ring

1. High chemical stability: Ceramic rings can resist corrosion from strong acids, bases, and other chemical properties;

2. Good high-temperature resistance: Under normal circumstances, the maximum operating temperature of ceramic rings can reach over 1000 ℃;

3. Strong wear resistance: Ceramic rings have excellent wear resistance and are not easily damaged after long-term use;

4. Good corrosion resistance: Ceramic rings have excellent corrosion resistance and usually do not exhibit corrosion;

5. Good filling effect: The surface roughness of the ceramic ring is extremely low, which can improve the filling effect and thus improve the efficiency of chemical reactions.

Product Detailed Pictures

|

|

Technical Data

| size mm | surface area m2/m3 | void fraction % | bulk number pieces/m3 |

| 16 | 250 | 87 | 300500 |

| 25 | 180 | 85 | 87040 |

| 30 | 170 | 85 | 55000 |

| 38 | 140 | 85 | 27600 |

| 50 | 110 | 84 | 10100 |

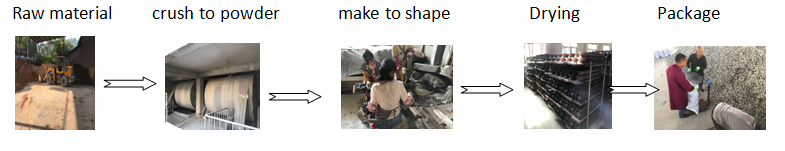

Prodution Process

Package Description

| Package | Carton Box, Woven Bag,Ton Bag, Wooden case | |||||

| Container | 20GP | 40GP | 40HQ | Normal order | Mininum order | Sample order |

| Quantity | 22CBM | 44CBM | 55CBM | less than 22CBM | 1CBM | less than 5pcs |

| Delivery time | 7days | 14days | 20days | 7days | 3days | stock |

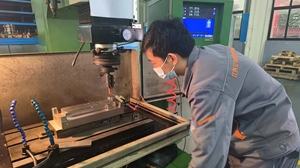

Factory Advantage

| Professional Mass Transfer Manufacturer | ||

|

|

|

| Digital Manufacturing Workshop | Product Design and Customize | Technical Support |

Customer Service

| OEM | ODM | EPC |

|

Annual production :30,000 cubic meters Production Capacity:28 advanced streamlined production lines |

Well-established R&D capabilities Designer with 15 years' experience |

One set of work from project design, purchase,construction to operation ,to provide customer a comprehensive solution. |

|

|

|

|

Application:

1. Used as fillers of polymer materials such as epoxy resin and polyimide;

2. Used as fillers used in processes such as gas-phase absorption, washing, and distillation;

3. Used as fillers in processes such as desulfurization, denitrification, catalyst removal, and dehydration in the fields of petroleum, chemical, metallurgical, and electric power