Material :

stainless steel,copper,metal,aluminium,nickelSpecification :

500BX,700CYAdvantage of Metal Structured Perforated Tower Packing

1.Large specifc surface area, high void ratio andlight.

2.Obliquity of gas passage is smal and regular, sopressure drop is low.

3.Good radial diffusion and sufhcient gas contact

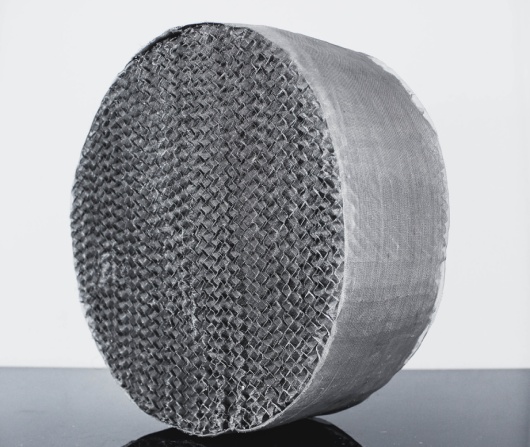

Product Detailed Pictures

|

|

Technical Data

| model | surface area m2/m3 | void fraction % | peak height mm | inclination angles |

| 500(BX) | 500 | 95 | 6.3 | 30 |

| 700(CY) | 700 | 87-90 | 4.5 | 45 |

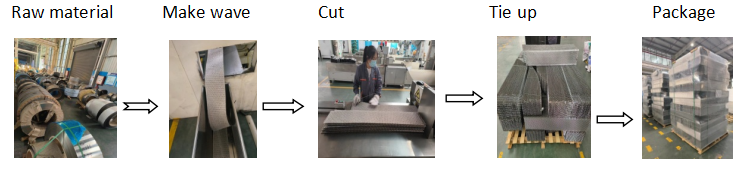

Prodution Process

Package Description

| Package | Carton Box, Woven Bag,Ton Bag, Wooden case | |||||

| Container | 20GP | 40GP | 40HQ | Normal order | Mininum order | Sample order |

| Quantity | 22CBM | 44CBM | 55CBM | less than 22CBM | 1CBM | less than 5pcs |

| Delivery time | 7days | 14days | 20days | 7days | 3days | stock |

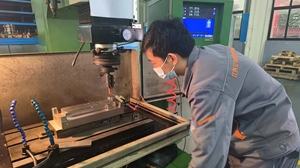

Factory Advantage

| Professional Mass Transfer Manufacturer | ||

|

|

|

| Digital Manufacturing Workshop | Product Design and Customize | Technical Support |

Customer Service

| OEM | ODM | EPC |

|

Annual production :30,000 cubic meters Production Capacity:28 advanced streamlined production lines |

Well-established R&D capabilities Designer with 15 years' experience |

One set of work from project design, purchase,construction to operation ,to provide customer a comprehensive solution. |

|

|

|

|

Application:

1. Metal wire gauze packing is used for Fine chemical, flavors factory, isomer separation. The separation of thermally sensitive materials, testing tower and the improvement of tower.

2. Precision rectification for high productive capacity and less theoretical plate number.