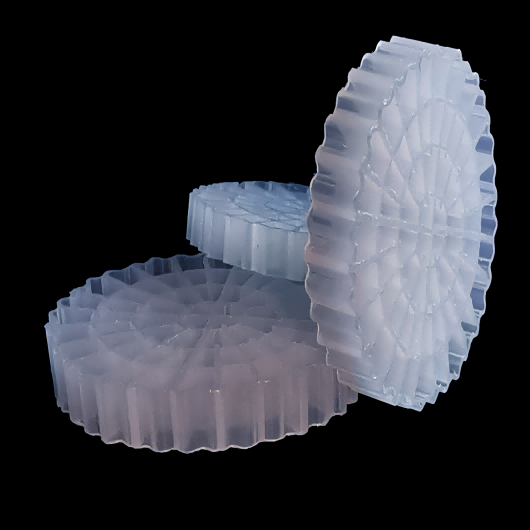

It is a type of wastewater treatment process that was first invented by Prof.Hallvard Degaard at University of Science and Technology in the lates of 1980s.The MBBR system consists of an aeration tank (similar to a activated sludge tank) with special plastic carriers that provide a surface where a biofilm can grow. The carriers are made of a material with a density close to the density of water (1 g/cm3). An example is high-density polyethylene (HDPE) which has a density close to 0.95 g/cm3. The carriers will be mixed in the tank by the aeration system and thus will have good contact between the substrate in the influent wastewater and the biomass on the carriers

Size :

25mm,10mmMaterial :

HDPEAdvantage of Plastic MBBR for Water Treatment

1.Large specific surface area, good hydrophilicity, high biological activity

2.Fast film hanging, good treatment effect, long service life

Product Detailed Pictures

|

|

Technical Data

| specification | hole quantity | density g/cm3 | surface area m2/m3 | porosity | membrane-forming time day | gNH4N/M3.d |

| 25*12 | 19 | more than 0.96 | more than 500 | more than 90 | 3-15days | 400-1200 |

| 25*4 | 64 | more than 0.96 | more than 1200 | more than 85 | 3-15days | 400-1200 |

| 10*10 | 4 | more than 0.98 | more than 900 | more than 85 | 3-15days | 400-1200 |

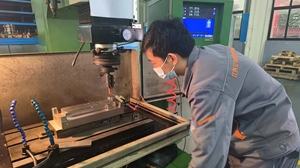

Prodution Process

Package Description

| Package | Carton Box, Woven Bag,Ton Bag, Wooden case | |||||

| Container | 20GP | 40GP | 40HQ | Normal order | Mininum order | Sample order |

| Quantity | 22CBM | 44CBM | 55CBM | less than 22CBM | 1CBM | less than 5pcs |

| Delivery time | 7days | 14days | 20days | 7days | 3days | stock |

Factory Advantage

| Professional Mass Transfer Manufacturer | ||

|

|

|

| Digital Manufacturing Workshop | Product Design and Customize | Technical Support |

Customer Service

| OEM | ODM | EPC |

|

Annual production :30,000 cubic meters Production Capacity:28 advanced streamlined production lines |

Well-established R&D capabilities Designer with 15 years' experience |

One set of work from project design, purchase,construction to operation ,to provide customer a comprehensive solution. |

|

|

|

|

Application: