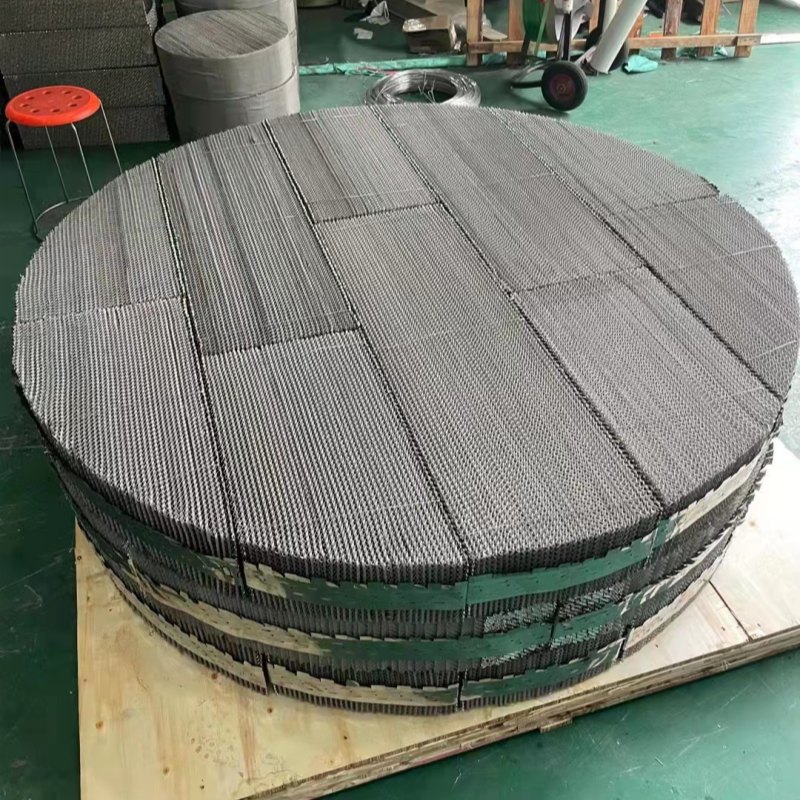

Metal perforated corrugated packing is a new type of high-efficiency packing made from metal sheets such as stainless steel and titanium through precision punching and corrugated forming processes. It has the following significant characteristics:

Large specific surface area (250-750 ㎡/m ³) 2. Porosity rate of over 95%

Theoretical board quantity can reach 3-5 pieces/meter

Reduce pressure to 30% -50% of traditional fillers

Application Industry Description:

Petrochemical industry: Ethylene/styrene separation, high-purity oxygen preparation, composite oil separation, epoxy propane separation, debutanizer, cyclohexane recovery, gasoline fractionation, atmospheric and vacuum refining, gasoline mercaptan removal, formaldehyde absorption tower, recycled ring tower, gasoline fractionation tower, catalytic reforming pre fractionation tower, refinery lubricating oil type vacuum tower, refinery catalytic cracking unit stabilization tower, aromatic hydrocarbon separation and solvent oil separation tower, depropanizer tower, pressurized distillation tower;

Fertilizer industry: comprehensive gas washing tower, saturated hot water tower, ammonia recovery tower, desorption tower, replacement saturated hot water tower, decarbonization tower, methanol distillation tower, ammonia recovery tower, washing tower, ammonia air mixer in nitrate compound fertilizer projects for gas production;

Environmental protection industry: devices for recovering nitrogen-containing ammonia water, waste acetone, high-purity dimethylformamide, acidic wastewater stripping tower, etc;

Coal chemical industry: coking plants recover crude benzene from coke oven gas through washing towers, desulfurization towers, benzene removal towers, oil removal devices, high-pressure ammonia washing towers, water washing towers, oil removal tanks, methanol absorption towers, water gas desulfurization towers, and purification devices for stripping towers in coal to urea projects.